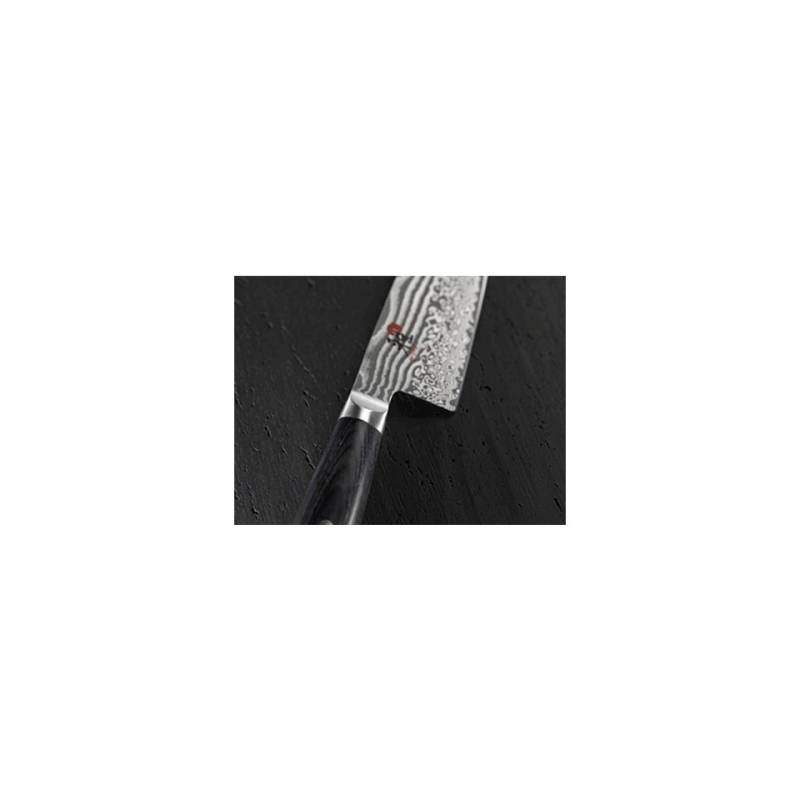

The Japanese Sujihiki Sashimi Miyabi Slicing Knife in Damascus Steel 24 cm will change the way you cook.

MIYABI 5000FCD SERIES

All Miyabi knives are made in Japan, where knife beauty meets unparalleled precision sharpening.KATANA DESIGN

Like most Japanese knives, the Gyutoh is inspired by the shape of a real katana.BLADE HARDNESS

The value is approximately HRC 61. This value is determined by the Rockwell hardness test, thanks to penetrators which, in this case, are conical in shape and made of diamond. Hardness is determined based on the elasto-plastic deformation of the tested material.As we said, the indenter is a diamond cone with an opening angle of 120° and 0.2 mm fillet radius.

HANDLE

Featuring the typical Japanese 'D-Handle' shape, it facilitates all cutting techniques.Made of Black Pakka Wood, it adopts steel end and red spacer in perfect Japanese style.

Pakkawood is a wood/plastic composite material that can closely resemble conventional wood.

It consists of pieces of hardwood veneer, often stained with bright colors, combined with plastic resins. The dye is impregnated into the wood using a vacuum process, and then the resin is added using a very high-pressure environment. The veneer pieces are stacked and compressed into plywood blocks containing about 29 pieces of wood per inch.

Composite woods, such as Pakkawood, closely resemble natural wood, but often come in a range of colors rarely seen in real wood.

The layered wood veneer gives the material the appearance of real wood grain.

Pakkawood is a very dense product that is largely waterproof, providing the same look and feel as wood, but without the warping and splitting common in real wood. This material holds up well in knife and tool handles, especially those exposed to humid and unfavorable environments. This type of composite wood has a very attractive glaze.

MOSAIC PIN

This is the metal rivet made with the metal technique and is located right in the middle of the handle.LASER TECHNOLOGY

Zwilling uses precision laser technology to test the quality and optimal cutting angle.AUTHENTIC JAPANESE-STYLE BLADE

It is made in Seki, an international hub of the Japanese sword and knife industry since the 14th century.The edge of the blade, according to Japanese tradition, has an angle of particularly narrow and symmetrical.

SAN MAY DAMASCUS STEEL BLADE WITH FC61 FINE CARBIDE CORE INSERT

The blade consists of an FC61 core that allows excellent cutting capabilities embedded in 48 layers of damascus steel that give it stability, strength and a unique design.Damascus steel is an alloy formed by multiple visible layers, also of different composition, which gives symmetry, elasticity.

FRIODUR®

Cryogenic tempering-that is, below zero-makes the blade extremely hard and durable.During a normal hardening process, a steel is rapidly cooled to achieve the martensitic transformation that gives it hardness. Note, however, that in the case of steels particularly rich in alloying elements, the martensitic transformation is not completed at room temperature.

With sub-zero treatment, however, the transformation from austenite to martensite is possible, thus allowing for structures that provide greater wear resistance and consequent increase in tool life .

Studies have been done to verify that with cryogenic treatment at -196 °C tool life, compared to treatment at -80 °C, reaches in some cases more than 3 times that provided by normal sub-zero treatment.

JAPANESE HONBAZUKE SHARPENING

This is a type of sharpening that originates from traditional Japanese knife making and is done on both sides. Each blade is sharpened by hand in 3 specific steps.Finally, the blade is initially machined using a special vertically rotating grinding wheel, followed by fine sharpening using a horizontally rotating grinding wheel.

Damascus steel knives are among the most sought-after and appreciated: take your chance on RG Mania!

If you need assistance regarding orders, returns, shipments click here.

If you want to know more about this product but haven't found the answer you were looking for in the description, ask your question here, we will answer you as soon as possible.

You must be registered to access this feature Login