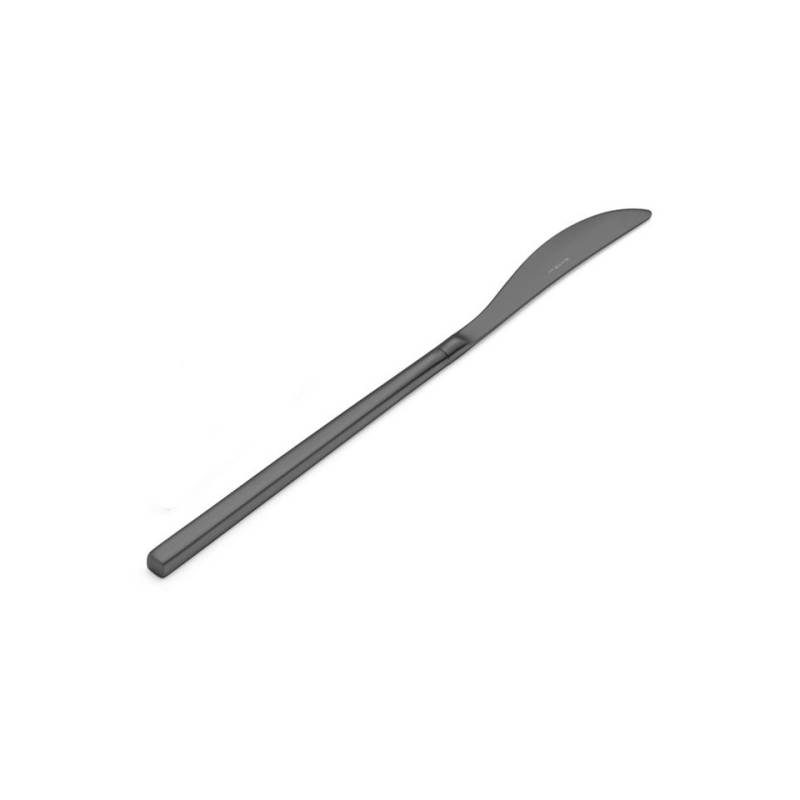

The Kyoto black sandblasted forged steel 22.9 cm Kyoto table knife is part of a line of sought-after, ultra-contemporary Eme cutlery that matches the boldest mise en place.

KYOTO SANDBLASTED BLACK FORGED STEEL TABLE KNIFE: FEATURES

The Kyoto Sand blasted Black line symbolizes the elegant restraint of the essential. This fully recyclable collection of forged cutlery in perfect Japanese style is made of 18/10 stainless steel with an elegant sandblasted matte PVD Black finish. The knives are specifically made of hardened martensitic steel (AISI 420), which ensures the durability of the blade's sharpness over time.The sandblasted finish, which is characterized by low roughness, is achieved by the technique of microbead blasting, a surface treatment of steel performed cold with ceramic microspheres launched under pressure. The object acquires a special aesthetic impact due to the reflected light diffused by the surface.

PVD stands for Physical Vapor Deposition. It is a technology used to color steel by deposition of very thin metal films inside vacuum chambers and consists of evaporation and subsequent condensation of metals on the cutlery. This treatment, with a range of wonderful shades of color, not only embellishes the cutlery but also makes it more resistant to wear and scratches and is a perfectly sustainable coating suitable for use in the food industry.

The main feature of this line is the simplicity of the design, which is iconic and almost childlike. The design was developed on the idea of purity, the balance between the lightness of the handle and the roundness of the products.

The neutral form, never banal, is highlighted by the detail of the engraved ring, the focal point between the squared handle and the conical part of the cutlery neck. It is this interrupting element that allows for additional combinations of colors and finishes, enabling the company to satisfy the greatest number of users.

Knives made of AISI 420 stainless steel are more susceptible to corrosion.

It is recommended to remove salt, vinegar, lemon and tomato-based sauce residues.

Also pay attention to dishwasher salt, which may play a corrosive role. After pouring the salt inside the reservoir and wiping any spills with a damp cloth, it would be advisable to run a vacuum wash cycle to remove any salt residue, which could otherwise damage the steel cutlery during the wash cycle.

BLACK SANDBLASTED FORGED STEEL KYOTO TABLE KNIFE: POSSIBLE PRESENCE OF RUST STAINS

EME cutlery (spoons, teaspoons, forks, ladles, etc.) is essentially made from two different types of steel alloys:AISI*304 - austenitic steel commonly called 18/10

AISI*430 - ferritic steel commonly called 18/C

EME KNIVES are exclusively manufactured from the following type of alloy:

AISI*420 - hardenable steel

In the composition of 18/10 steel for the production of cutlery there may be a percentage of Nickel, while in the latter it is totally absent. It is the only hardenable steel and through this heat treatment it increases its mechanical properties, which allow, for example, knife blades to be sharp. Both types CANNOT rust, if by rust we mean iron oxide. Over time, however, dark and/or rusty spots may appear on surfaces, caused by external contamination of the cutlery; not an actual attack of the stainless steel. The most common causes of the generation of these stains are rubbing the cutlery with steel wool dunnage, contact with iron/steel items, or contamination with water with high dissolved iron content. However, these stains are easily removed with a steel cleaning product. Small rust stains may also form on knife blades, especially after washing in the dishwasher.

*American Iron and Steel Institute (AISI)

BLACK SANDBLASTED FORGED STEEL KYOTO TABLE KNIFE: POSSIBLE CAUSES OF OXIDATION

Here are the possible causes of oxidation of this type of knife:- Dishwasher electrical discharge

All dishwashers, whether for private or professional use, during washing cycles produce small electrical discharges inside that normally do not impact china, glasses, cutlery (spoons, teaspoons, forks, etc.). Introducing galvanized, tin-plated (pastry utensils), aluminum (cookware or lids) items increases by reaction the formation of these small discharges that are exclusively attracted to knife blades precisely because of the very composition of the steel alloy described above.

This phenomenon can also occur with the simultaneous introduction into the dishwasher of knives and porcelain items with significant decorations; in fact, the composition of the porcelain's coloring causes an effect similar to that of aluminum and

can damage knife blades.

The stains created in the first episodes are not highly corrosive, and it is recommended that they be removed with a sponge and neutral detergent so that the problem does not become a larger one.

- Chlorine dioxide in drinking water.

For the past couple of years, worldwide, Chlorine Dioxide (ClO2) has been included as a disinfectant in the drinking water stage instead of Sodium Hypochlorite (Bleach - NaClO) or Chlorine Gas.

While noting the greater disinfectant efficacy of Chlorine Dioxide, 5 times greater than Chlorine Gas, there are contraindications during use at temperatures

high above 60 degrees, as occurs during the dishwasher cycle. At this temperature there is a tendency for Chloric Acid (HClO2) to form: in fact, it is an aggressive agent for martensitic steels used in cutlery.

This phenomenon is so pronounced that already at the first wash, on new pieces in the dishwasher, signs of corrosive attack can appear on the blades and knives, called pit corrosion, i.e., small rust spots destined to become larger.

To minimize the problem, one must limit the period of contact of the vapors at temperature with the knives. Therefore, as soon as washing is finished, knives should be removed from the dishwasher, wiped with a soft cloth, as well as for pieces that appear dry.

For professional users, restaurants, bars, cafeterias, communities, it is recommended to install a dechlorinator upstream of the washing system, which will significantly reduce the amount of Active Chlorine in the water.

- Maintenance and/or external contamination

The causes of oxidation are always external; due precisely to improper maintenance or contamination.

Stainless steel can oxidize by the action of strong acids, such as sulfuric and sodium chloride, or by substances contained in food that produce a corrosive process on its surfaces, such as: acetic, citric, lactic acid, etc.

BLACK SANDBLASTED FORGED STEEL KYOTO TABLE KNIFE: DAILY MAINTENANCE DIRECTIONS

Finally, some daily maintenance directions for the Kyoto Sandblasted Black Eme table knife:- Wash the cutlery well after use and never leave it dirty for prolonged times.

- Avoid using abrasive items that can produce scratches on the surface of steel products.

- Never leave cutlery submerged in water for long periods of time.

- Rinse all pieces with water before placing them in the dishwasher basket.

- Place knives with the blade facing downward.

- At the end of the washing program, remove the cutlery as soon as possible and, if necessary, dry it; if this is not possible, open the dishwasher door so that steam can escape and moisture does not accumulate.

- Use only high-quality detergents and follow the instructions on the detergent package so that you will always have excellent results.

- Always check the composition of items fed into the dishwasher.

- Always follow the instructions in the dishwasher's booklet.

If you need assistance regarding orders, returns, shipments click here.

If you want to know more about this product but haven't found the answer you were looking for in the description, ask your question here, we will answer you as soon as possible.

You must be registered to access this feature Login